4000bph Water Line

Related Products

2500BPH 3 Cavity Stretch Blow Molding Machine

This stretch blow molding machine is a fully automatic PET stretch blow molding machine specially designed by our company, The bottle making process is done fully automatically eliminating costly labors and reducing cost of power consumption. It is best partner of bottled water filling line with capacity of 2000 to 3000 bottles per hour.

| Model | HZ-880B |

| No of Cavity | 3 Cavity |

| Applicable Preform Material | PET |

| Bottle Size | 50-1500ml |

| Output Capacity | 2500-2800 BPH |

| Power Consumption | 15 kw |

| Power Supply | 220~380V/50~60 HZ |

| Machine Dimension(L x W x H) | 2.0×0.85×2.2 M |

| Machine Weight | 1200kgs (approx) |

| Preheater Dimension(L x W x H) | 1.5×0.85×2.2 |

| Preheater Weight | 500 kgs(approx) |

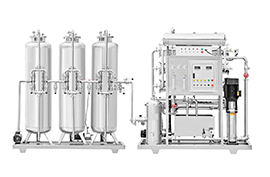

WT-RO-5000 Prefiltration and Reverse Osmosis

WT-RO-5000 commercial and industrial reverse osmosis systems are engineered to economically produce high purity water by removal of dissolved minerals, bacteria, particles, and organic impurities. Each machine is constructed using the highest quality components and materials for reliable operation and exceptional performance.

| Model No | WT-RO-5000 |

| Capacity | 5000LPH(Liter per Hour) |

| Nominal Recovery | 65-75% |

| Nominal Salt Rejection | 99.60% |

| Operating Temperature | 15°C-45°C |

| Design Temperature | 25°C |

| Feed Pump | 1.1KW |

| High Pressure Pump | 5.5KW |

| Voltage | 220V /380V/460V - 50Hz/60Hz |

4000-5000 Bottles per Hour Water Filling Machine

This automatic water bottle filling machine is a fully automatic rotary filling machine for bottle water filling and non-carbonated drink filling that are packed in plastic bottles ranging from 200ml to 1500ml, which includes 14 rinse valves, 12 fill heads and 5 cap head assemblies, Speed of 4000 to 5000 bottles per hour can be achieved on this durable and dependable automatic water filling machine.

| Model | CGF 14-12-5 |

| Output Capacity | 4000-5000Bottles/Hr at 500ml volume |

| Nos of Rinse Valves | 14 |

| Nos of Fill Heads | 12 |

| Nos of Cap Heads | 5 |

| Applicable Bottle Diameter | Φ50 mm ~Φ90 mm |

| Applicable Bottle Height | 150 mm - 310 mm |

| Applicable Screw Cap Diameter | Φ25 mm ~Φ35 mm |

| Applicable Screw Cap Height | 15 mm - 25 mm Screw Cap |

| Supply Voltage | 220/380V 50/60HZ 3PH |

| Main Motor | 1.5KW |

| Weight | 2500 kgs(approx) |

| Dimension(Without Conveyor) | 2400 x 1700 x 2150 mm |

Steam Shrink Tunnel

This series water bottling machines have been engineered for start-up companies to pack purified water, mineral water and non-carbonated drinks in PET bottles from 200ml to 1500ml, integrating rinsing, filling and capping into one, which includes 8 rinsing valves, 8 filling heads and 3 capping head assemblies. 2000 to 3000 bottles per hour can be achieved.

- Over all stainless structure

- Easy to install and operation adjustment is convenient

- Suitable for PVC, PET, OPS shrink packaging materials

- Suitable for round, square, oval-shaped, curve-shaped containers

- Shrinkage capability 450BPM to 600BPM

- Stand Frame Adjustable

- Drip tray

- Individual Valve control will be included

- Exhausted blower

Specifications are subject to change without notice, All rights are reserved

High Speed Shrink Sleeve Label Machine

High speed shrink sleeve label machine is designed for high volume production rates to deliver and shrink a consistent stream of sleeve labels and tamper evident bands on a variety of empty or filled round, square, rectangular, oval containers in plastic, glass and metal widely used for beverage, food…

| Model No | SLM-350 | SLM-450 | SLM-600 |

| Speed Range | 350BPM | 450BPM | 600BPM |

| Container Shape | Round, square, rectangular and oval containers with contours | ||

| Container Type | Glass, plastic and metal | ||

| Sleeve Label Material | PVC, PET, OPS, & OPP | ||

| Material Thickness | 0.03-0.13mm | ||

| Container Dimeters | 28-125mm | ||

| Container Height | 50-305mm | ||

| Sleeve Lay Flat | 25-200mm | ||

| Sleeve Cut Length | 38-305mm | ||

| Core Size | 5″- 10″Adjustable | ||

| Full Spool Outside Diameter | 500mm | ||

| Electric Supply | 220V 50/60HZ 1/3PH;380V 50/60HZ 3PH | ||

| Machine Dimension | 2.1×1.1x2M | 2.1×1.2x2M | 2.5×1.2×2.2M |

| *Speed Dependent on Sleeve Length and Width. | |||

L type Automatic Shrink Wrap Machine

L type automatic shrink wrap machine is fully automatic industrial shrink wrap machine used to pack either as individual packs like carton or as collations, Applications include transit collation of bottles, jars and canned products and industrial products.

| Packing Speed | 8-10Packs/Min |

| Max Pack Size | 600(L)x400(W)x350(H)mm |

| Applicable Film | Polyethylene(PE) Film |

| Max Film Width | 600mm |

| Max Film Thickness | 100Micro |

| Conveyor Electric Supply | 220V 50/60HZ 1PH 0.75KW |

| Sleeve Wrapper Electric Supply | 220V 50/60HZ 1PH 1.20KW |

| Shrink Tunnel Electric Supply | 380V 50/60HZ 3PH 26.00KW |

| Shrink Tunnel Chamber | 1800x600x400mm |

| Conveyor Dimension | 2700x350x900mm |

| Sleeve Wrapper Dimension | 1500x910x2000mm |

| Shrink Tunnel Dimension | 3300x900x1850mm |

| Idle Roller Conveyor | 1200x800x950mm |

| Conveyor Weight | 180kgs |

| Sleeve Wrapper Weight | 500kgs |

| Shrink Tunnel Weight | 600kgs |

| Idle Roller Weight | 60kgs |