4000bphウォーターライン

Related Products

2500BPH 3キャビティストレッチブロー成形機

This stretch blow molding machine is a fully automatic PET stretch blow molding machine specially designed by our company, The bottle making process is done fully automatically eliminating costly labors and reducing cost of power consumption. It is best partner of bottled water filling line with capacity of 2000 to 3000 bottles per hour.

| モデル | HZ-880B |

| キャビティ数 | 3キャビティ |

| 適用プリフォーム材料 | PET |

| ボトルサイズ | 50-1500ミリリットル |

| 出力容量 | 2500~2800BPH |

| 消費電力 | 15キロワット |

| 電源 | 220~380v/50~60 hz |

| 機械寸法(長さ×幅×高さ) | 2.0 x 0.85 x 2.2 M |

| マシン重量 | 1200kg(約) |

| プレヒーター寸法(長さ×幅×高さ) | 1.5×0.85×2.2 |

| プレヒーター重量 | 500キログラム(約) |

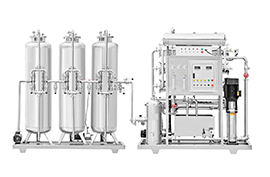

WT-RO-5000 Prefiltration and Reverse Osmosis

WT-RO-5000 commercial and industrial reverse osmosis systems are engineered to economically produce high purity water by removal of dissolved minerals, bacteria, particles, and organic impurities. Each machine is constructed using the highest quality components and materials for reliable operation and exceptional performance.

| Model No | WT-RO-5000 |

| 定員 | 5000LPH(Liter per Hour) |

| Nominal Recovery | 65-75% |

| Nominal Salt Rejection | 99.60% |

| Operating Temperature | 15°C-45°C |

| Design Temperature | 25°C |

| Feed Pump | 1.1KW |

| High Pressure Pump | 5.5KW |

| 電圧 | 220V /380V/460V – 50Hz/60Hz |

4000-5000 Bottles per Hour Water Filling Machine

この自動水びんの充填機はびんの水詰物および非炭酸飲み物の詰物のためのフル オートの回転式充填機です200ml から 1500ml までのプラスチックびん詰めにされる、14 の洗浄弁、12 の盛り土の頭部および 5 つの帽子のヘッド アセンブリを含んでいます。この耐久性があり、信頼できる自動水充填機で 1 時間あたりのびんは達成することができます。

| モデル | CGF 14-12-5 |

| 出力容量 | 4000-5000Bottles/Hr at 500ml volume |

| リンスバルブ数 | 14 |

| フィルヘッドの数 | 12 |

| キャップヘッド数 | 5 |

| 適用ボトル径 | Φ50 mm ~Φ90 mm |

| 適用ボトルの高さ | 150 mm - 310 mm |

| 適用スクリューキャップ径 | Φ25 mm ~Φ35 mm |

| 適用スクリューキャップの高さ | 15 mm - 25 mm スクリューキャップ |

| 電源電圧 | 220/380v 50/60hz 3ph |

| メインモーター | 1.5KW |

| 重量 | 2500 kgs(approx) |

| 寸法(コンベアなし) | 2400 x 1700 x 2150 mm |

スチームシュリンクトンネル

This series water bottling machines have been engineered for start-up companies to pack purified water, mineral water and non-carbonated drinks in PET bottles from 200ml to 1500ml, integrating rinsing, filling and capping into one, which includes 8 rinsing valves, 8 filling heads and 3 capping head assemblies. 2000 to 3000 bottles per hour can be achieved.

- Over all stainless structure

- Easy to install and operation adjustment is convenient

- Suitable for PVC, PET, OPS shrink packaging materials

- Suitable for round, square, oval-shaped, curve-shaped containers

- Shrinkage capability 450BPM to 600BPM

- Stand Frame Adjustable

- Drip tray

- Individual Valve control will be included

- Exhausted blower

Specifications are subject to change without notice, All rights are reserved

High Speed Shrink Sleeve Label Machine

High speed shrink sleeve label machine is designed for high volume production rates to deliver and shrink a consistent stream of sleeve labels and tamper evident bands on a variety of empty or filled round, square, rectangular, oval containers in plastic, glass and metal widely used for beverage, food…

| Model No | SLM-350 | SLM-450 | SLM-600 |

| Speed Range | 350BPM | 450BPM | 600BPM |

| Container Shape | Round, square, rectangular and oval containers with contours | ||

| Container Type | Glass, plastic and metal | ||

| Sleeve Label Material | PVC, PET, OPS, & OPP | ||

| Material Thickness | 0.03-0.13mm | ||

| Container Dimeters | 28-125mm | ||

| 容器の高さ | 50-305mm | ||

| Sleeve Lay Flat | 25-200mm | ||

| Sleeve Cut Length | 38-305mm | ||

| Core Size | 5″- 10″Adjustable | ||

| Full Spool Outside Diameter | 500mm | ||

| 電気供給 | 220V 50/60HZ 1/3PH;380V 50/60HZ 3PH | ||

| 機械寸法 | 2.1×1.1x2M | 2.1×1.2x2M | 2.5×1.2×2.2M |

| *Speed Dependent on Sleeve Length and Width. | |||

L型自動シュリンク包装機

L type automatic shrink wrap machine is fully automatic industrial shrink wrap machine used to pack either as individual packs like carton or as collations, Applications include transit collation of bottles, jars and canned products and industrial products.

| Packing Speed | 8-10Packs/Min |

| Max Pack Size | 600(L)x400(W)x350(H)mm |

| Applicable Film | Polyethylene(PE) Film |

| Max Film Width | 600mm |

| Max Film Thickness | 100Micro |

| Conveyor Electric Supply | 220V 50/60HZ 1PH 0.75KW |

| Sleeve Wrapper Electric Supply | 220V 50/60HZ 1PH 1.20KW |

| Shrink Tunnel Electric Supply | 380V 50/60HZ 3PH 26.00KW |

| Shrink Tunnel Chamber | 1800x600x400mm |

| コンベア寸法 | 2700x350x900mm |

| Sleeve Wrapper Dimension | 1500x910x2000mm |

| Shrink Tunnel Dimension | 3300x900x1850mm |

| Idle Roller Conveyor | 1200x800x950mm |

| コンベア重量 | 180kgs |

| Sleeve Wrapper Weight | 500kgs |

| Shrink Tunnel Weight | 600kgs |

| Idle Roller Weight | 60kgs |